Stone Finish

We are capable of doing various kinds of finish for the stone products, such as follows.

Sawn cut, natural split, honed, flamed, bush hammered, pineapple, fine picked, rough picked, flamed and brushed, bush hammered and brushed, sandblasted, tumbled, antique, acid-washed, natural cleft, waterjet, brushed, hand-cut, machine cut, machine pulled, groove, fine lined, mushroom surface, filled, grinded and any other finishes you may require. If you have any special finish, you may contact us or provide us with the drawings, we will be able to customize it for you.

Below are explanations to some typical surface finishes:

Polished:

To smooth or brighten a surface increasing the reflective quality and luster by chemical or physical processes. Generally gloss levels could be measured by a gloss meter.

Honed:

To grind a surface with a high grit material to a uniform specification without producing a reflective surface.

Flamed:

This surface is rough in texture and is developed through intense heat during fabrication. The stone is heated and crystals begin to pop, thus forming a rough surface. This surface is very porous and must be treated with Stoneguard.

Ancient (flamed and brushed): Brush the flamed surface to make it more smooth.

Tumbled:

It gives the stones an archaic appearance. The slightly rough texture is achieved by tumbling small pieces of marble, limestone, and sometimes granite. It often requires application of Stone Color Enhancer to bring out the colors.

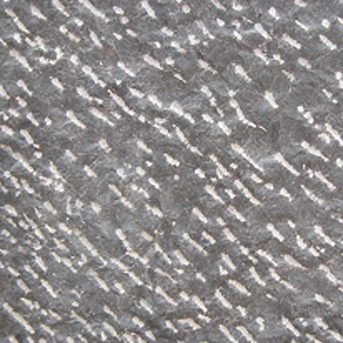

Sandblasted:

Pressurized flow of sand and water that provides the stone a matte, textured surface.

Bush Hammered:

This rough, textured surface is developed through pounding action on the stone. The degree of roughness is controllable.

Sawn:

i.e. unpolished. It is not advisable to buy this way because : floor polishers do not give as good a polish as factory machine polishers. Many defects are not visible easily before polishing.

Mushroom:

in fact, the finish is natural cleft. Just the appearance is like a "Mushroom".

Filled:

When travertine is used for tiles and slabs, it is usually "filled"—that is, the surface holes are filled with cement or sometimes epoxy, and then polished or honed like any other stone tiles or slabs.

waterjet surface: it is usually done by a high pressure of around 25000 PSI, the surface will become rough and more importantly this finish could restore the color.

Calibration:

To grind a surface with a high grit material to a uniform surface to maintain the thickness variation.

Gangsaw:

To grind two sides of the stone surfaces with a high grit material to a uniform specification without producing a reflective surface.

Free lengths:

i.e. lengths varying randomly while width is constant are also very attractive. Choose the widths as per the expected floor area. Buy random lengths and cut at your site to fit.

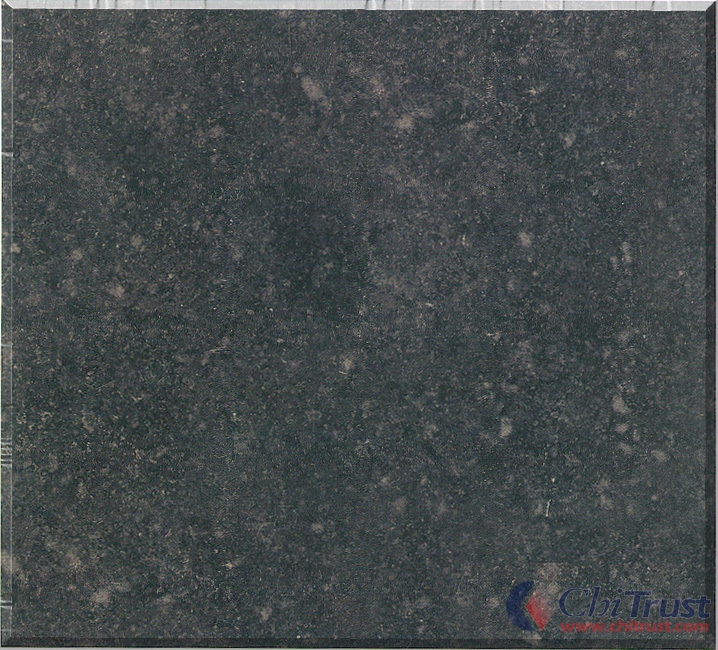

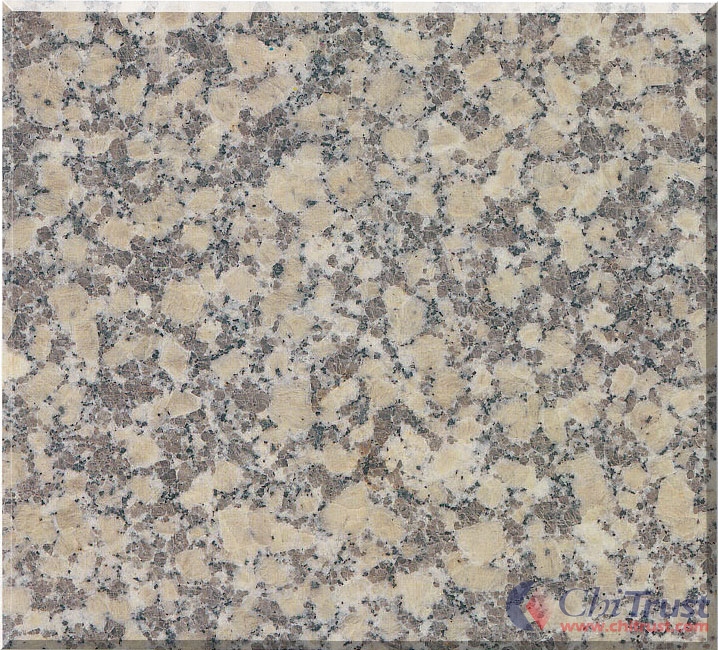

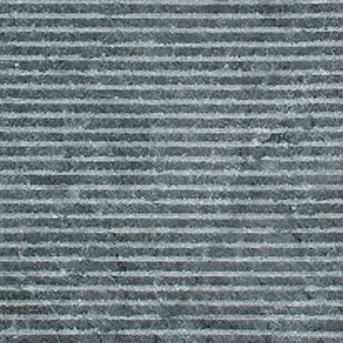

Below are some pictures to show you some typical surface finishes.

|

|

|

| Bluestone Flamed | Bluestone Antique Finish | Bluestone Honed+bush hammered |

|

|

|

| Bluestone Pineapple | Bluestone Honed and tumbled | Bluestone Bush hammered |

|

|

|

| Bluestone Sandblasted | Bluestone Chopper | Bluestone Lined Option 1 |

|

|

|

| Bluestone Lined Option 2 | Bluestone Chisselled | Bluestone Honed |

|

|

|

| Basalt SpringRain | Basalt Cloth Surface | Basalt Irregular Planed |

|

|

|

| Basalt Fined Grooved | Basalt Planed Flat | Basalt fine lined |

Previous: London England Stone Exhibition 2017-04

Recommendation Stone

Recommended News